So one of the tricks to arriving at a fair hull involves applying a thin layer of microbaloons and epoxy over the entire surface and then hand sanding all 44 ft. of this boat with a "long board". By applying this layer with a grooved spreader, the resulting surface can then be sanded so that just the tips of the grooves need to be knocked down. One day, once I decide its time to stop sanding, I'll go over the entire surface with a sheet rock blade filling in the remaining groove recesses.

here's a photo looking up towards the port side gunwale

The grooved spreader produces an approximate 3/16 inch deep pattern

another photo showing the portion of the hull just above the port side center board slot

Here's the notched spreader that I am using to create the surface to be sanded. The sanding board is made from a 4ft long piece of western cedar covered with 24 grit sand paper.

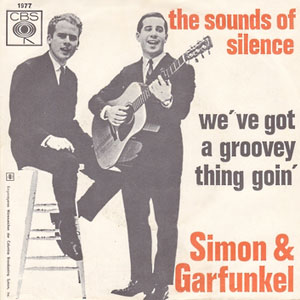

Groovy (or, less common, "Groovie") is a slang colloquialism popular during the 1960s and 1970s, springing out of African American culture. It is roughly synonymous with words such as "cool", "excellent", "fashionable", or "amazing", depending on context.

The word originated in the jazz culture of the 1920s, in which it referred to the groove of a piece of music[1] and the response felt by its listeners. It is a reference to the physical groove of a record in which the pick-up needle runs. It first appeared in print in Really the Blues, the 1946 autobiography of the jazz saxophonist, Mezz Mezzrow.[2] The term in its original usage had largely vanished from everyday use by 1980.[3]

Starting in the mid-1960s, variations of the word "Groovy" were used in the titles of several popular songs:

2 comments:

How big an area do you do at once? I'm also wondering if it's worth making my own fairing compound or buying the ready made stuff. How much did you use per hull side?

In response to She:Kon's comment...I've been making my own fairing compound to do the more obvious wobbles and once I walk out to the shop and decide to stop sanding, I'll do a thin skim coat of System Three Quick fair. The stuff is insanely expensive bit really goes on nicely and in this instance, it bonds to the 20 grit long board sand paper marks and makes it possible to switch right over to 220 grit. for the bulk fairing compound, settled in on mixing batches of filler by adding a little more than 2 quarts of micro balloons into a 5 gal bucket. In a separate 2 quart pitcher, I then mix a pint of A side with a half pint of B then mixing the resin first with a drill and paint mixer; dumping the mixed epoxy into the bucket then mixing it all up to the consistency of soft peanut butter. Even know I use slow hardener for this, since it's a fair quantity of compound, you get about 10 minutes to smooth it out on the hull.

Post a Comment