11.02.2010

Rudder blanks

My plan is to create two planks from a total of 20 pieces of 3/4 x 4 in cedar. After this photo was taken, I mixed up a batch of cabocil and epoxy then slathered each edge and face with the mixture then placed the entire laminated block into a vacuum bag to insure that both planks were bonded well.

Next step will be to take a little time with a chisel and mallet cutting out a hollow portion that will allow the rudder shaft to be positioned between the two blanks. Then another session of epoxy goo and vac bagging the cedar blanks over the rudder post to form a block with the rudder shaft in the middle of it. Once done, the fun part becomes shaping of that the streamlined profile with a power planer.......at least that's the plan.

10.30.2010

Play testing

This resulted in a super lightweight and strong piece that showed very little deflection when loaded.

The photo is somewhat mis-representational in that the curve of this composite structure is molded in and I have not yet reached my full body weight. The keen eye may also take note of the clever use of a middle eastern camel saddle being used as the support for the Targa Bar.

As a final note, It's also safe to say that throughout all of written history, this may be the only time that a sentence containing both targa bar and camel saddle has been produced. If I may go further, this may also be the only time that a carbon fiber targa bar has come into actual contact with a sinew laced leather bound middle eastern camel saddle whose marriage resulted in a fine teeter totter which we enjoyed immensely.

10.25.2010

Targa bar post cure oven

10.22.2010

Two 6082 alloy aluminum Rudder shafts

?

Truth be told......they were built according to the fabricated parts book that is part of the licensing of the F-44SC Super Cruiser by Ian Farrier.

These beauties were fabricated from a particularly difficult to find 6082 Aluminum. ( for reasons unknown to me, this alloy is readily available in europe, england and other locales but is next to impossible to find state side.)

6082 Aluminium (Al Si1 Mg Mn)

Fairing before the storm

At present, there is a low pressure about to slam into the Pacific NW so I am taking advantage of the decent weather and applying the first of three fairing coats. Although System Three offers a product called Quick fair, the cost factor is orders of magnitude different that mixing up medium sized batches of resin and microbaloons. System three boasts that Quickfair is superior because of it being formulated under vacuum therefore eliminating air in the mix. At $150 bucks a gallon, to me, I have decided that it isn't worth the little extra effort of mixing up my own fairing compound.

10.18.2010

Targa Bar

10.15.2010

4 burner

10.08.2010

Harken the Harold angels sing.....

10.04.2010

Hitting the ground running on my cat...

The forward member that ties the two bow sections together requires a large radius "fillet" on thr under side of each end the beam where they penetrate the hulls.

Next I have created two foam core shapes that sculpt to a pleasing shape in preparation of several layers of unidirectional glass and for good measure a bit or carbon Uni to make me feel a little better.

just for the heck of it, here that cat taking shape:

9.23.2010

9.18.2010

forgive the tangent post

hi guys....headed back to Alabama to get my dad's John Hanna Gulfweed "Lyncoya" back in shape for a nice sail in mobile bay with friends and family then headed back up to Hood River, OR. Too bad the cooler's not big enough for all the cold drinks we'd need for all you blog followers.

I'll be back in oregon in two weeks to finish the cat then we're gonna load up the family, sail down the west coast through the panama canal and stop in again to Fly creek Marina in Fairhope, Alabama to make sure the bildge is dry in my dads boat. From there, it's on towards the west indease and maybe trace some of the return voyages of that Chris Columbus guy who decimated the local population of north america..

I'll place a few before and after shots of "Lyncoya" in the next post then I'll resume posting the rest of the build of this F-44SC Cat. "Mariana".

Sorry for the tangent post.......

9.15.2010

On-board sanitation

Here's the link: http://www.airheadtoilet.com/

9.08.2010

Half a horse powered margarita

In full sun, these panels will produce about 360 Watts of power. With one horse power being 746 Watts , that's a half a horse galloping up on the cabin top. In addition to this, I plan to balance this out with another 500W of wind power. Since the sun and the wind are still free, it's nice to know that once all the systems are in place, we'll be able to put frozen reverse osmosis water into a 12 volt blender and make margaritas in the 90 degree heat of the tropics.

9.05.2010

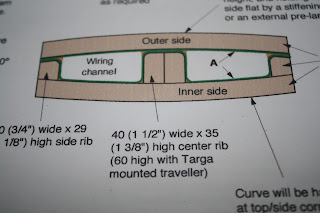

window opening edge detail

I chose to use the strongest of the three edge detail options that are specified in the plans by Ian Farrier.

Although my technique was certainly not the most elegant, I was able to create high density cores around the edges of the window openings by filling the1 inch voids using gallon sized zip lock bags full of epoxy/ microbaloon filler with the corner cut off. I then ran 1 1/8 wide strips of a heavy synthetic roofing membrane along the edges which created an edge mold to keep the goo in place.

Although my technique was certainly not the most elegant, I was able to create high density cores around the edges of the window openings by filling the1 inch voids using gallon sized zip lock bags full of epoxy/ microbaloon filler with the corner cut off. I then ran 1 1/8 wide strips of a heavy synthetic roofing membrane along the edges which created an edge mold to keep the goo in place.  The corners and sides were smoothed down and the straight portions were backed with wood strips held in place with duct tape.

The corners and sides were smoothed down and the straight portions were backed with wood strips held in place with duct tape.9.03.2010

trampoline study

9.01.2010

a foam core removal tool

I designed and built a custom foam removal tool that allowed me to strengthen the edges of the window openings. This tool uses four water jet cut "blades" fastened to a spindle that has an aluminum hand grip on one end. This tool really works and removes the foam core while leaving the fiberglass edge reinforcement.

I designed and built a custom foam removal tool that allowed me to strengthen the edges of the window openings. This tool uses four water jet cut "blades" fastened to a spindle that has an aluminum hand grip on one end. This tool really works and removes the foam core while leaving the fiberglass edge reinforcement.  Since I was taking this photo with one hand, I was not able to show myself holding the aluminum support handle with my other hand. With one hand on the drill and the other supporting the end, this tool does a fine job removing foam core. This open space will later be filled with a mixture of epoxy and glass microbaloons. The edges will then be covered over with a wrap of DBM tape. Once complete, polycarbonate glazing will be fastened along these reinforced edges.

Since I was taking this photo with one hand, I was not able to show myself holding the aluminum support handle with my other hand. With one hand on the drill and the other supporting the end, this tool does a fine job removing foam core. This open space will later be filled with a mixture of epoxy and glass microbaloons. The edges will then be covered over with a wrap of DBM tape. Once complete, polycarbonate glazing will be fastened along these reinforced edges.  here is the finished window opening after using the foam removal tool to create a 1 inch a deep foam free edge.

here is the finished window opening after using the foam removal tool to create a 1 inch a deep foam free edge. 8.29.2010

I spent a little time transferring the shapes onto the cabin sides markimg inch and a half offsets with a sharpy. I then spent and hour or two cutting the window openings using a carbide blade on a nice Bosch saber saw. Ian is correct in stating that the positioning of the windows is crutial to the overall characteristic look of the Farrier boat. I imagine round Popeye port hole would make for an interesting look but usually it's considered in poor taste to change the basic look of a licensed boat. Some people go as far as suggesting that you will burn in hell for eternity so I didn't want to risk it. I think they look pretty good. If it didn't blow the weight budget, I'd go with the 2 inch thick laminated bullet proof polycarbonaet for those coastal cruises off the coast of Somalia.